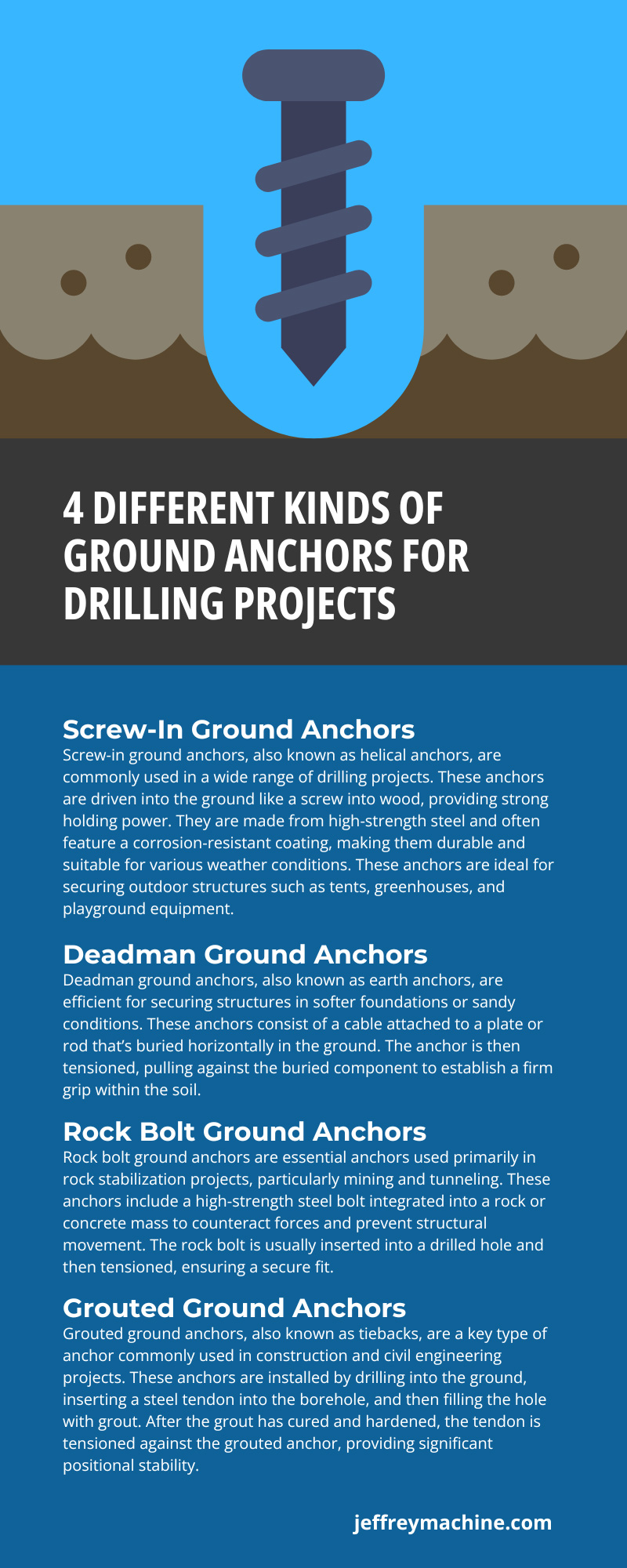

4 Different Kinds of Ground Anchors for Drilling Projects

Before beginning a drilling project, one of the most critical considerations you must make is the type of ground anchor to use. This essential tool provides the necessary support and stability to ensure the project’s smooth operation. Various ground anchors, each with distinct characteristics and applications, cater to different drilling projects’ diverse and specific needs. From expansive construction sites to compact home improvement ventures, there is a ground anchor perfectly suited for every drilling endeavor. This overview of the different kinds of ground anchors for drilling projects will help you determine which is right for your application.

Screw-In Ground Anchors

Screw-in ground anchors, also known as helical anchors, are commonly used in a wide range of drilling projects. These anchors are driven into the ground like a screw into wood, providing strong holding power. They are made from high-strength steel and often feature a corrosion-resistant coating, making them durable and suitable for various weather conditions.

These anchors are ideal for securing outdoor structures such as tents, greenhouses, and playground equipment. In larger construction projects, they offer stability in areas prone to soil erosion or where additional support for structures is needed. Installation of screw-in anchors is generally straightforward, requiring only a steel rod or power-driving equipment. Easy to install and remove, they offer a practical and versatile anchoring solution for various projects.

Deadman Ground Anchors

Deadman ground anchors, also known as earth anchors, are efficient for securing structures in softer foundations or sandy conditions. These anchors consist of a cable attached to a plate or rod that’s buried horizontally in the ground. The anchor is then tensioned, pulling against the buried component to establish a firm grip within the soil.

Thanks to their excellent holding capacity, deadman anchors are often used in civil engineering projects such as retaining walls and slope stabilization. They are also ideal for anchoring boats and floating docks, as they hold well in muddy or sandy bottom conditions. While installation of deadman ground anchors can be more labor-intensive than screw-in types, their superior holding power in soft soil conditions makes them a valuable tool in specific applications.

Rock Bolt Ground Anchors

Rock bolt ground anchors are essential anchors used primarily in rock stabilization projects, particularly mining and tunneling. These anchors include a high-strength steel bolt integrated into a rock or concrete mass to counteract forces and prevent structural movement. The rock bolt is usually inserted into a drilled hole and then tensioned, ensuring a secure fit.

Rock bolt ground anchors are used when geological conditions with a risk of rock falls or landslides are present, such as steep slopes or cliff faces. These anchors’ robust construction and anchoring mechanisms ensure excellent stability in these challenging environments. Installation typically requires more specialized equipment and ability than other anchor types, reflecting the complexities of working with rock and concrete substrates. Despite this, rock bolt ground anchors offer a highly effective solution for anchoring in solid rock conditions and are indispensable in maintaining safety and integrity in mining and tunneling projects.

Grouted Ground Anchors

Grouted ground anchors, also known as tiebacks, are a key type of anchor commonly used in construction and civil engineering projects. These anchors are installed by drilling into the ground, inserting a steel tendon into the borehole, and then filling the hole with grout. After the grout has cured and hardened, the tendon is tensioned against the grouted anchor, providing significant positional stability.

Projects requiring high load-bearing ability and superior resistance to movement, such as securing excavations, supporting retaining walls, and stabilizing slopes, use grouted ground anchors. They are particularly effective in dense soil and rock conditions where the grout can tightly bond with the surrounding material, ensuring a highly secure anchor. Installation of grouted ground anchors calls for specialized knowledge and equipment, making these anchors more suitable for larger-scale, professional projects. Notwithstanding their complexity, grouted ground anchors deliver unparalleled anchoring strength and reliability, making them a top resource in many construction and engineering endeavors.

Choosing the Right Ground Anchor

Choosing the right ground anchor for your drilling project ensures its success and safety. Consider the nature of your project, the geographical and soil conditions, and the specific anchoring needs. For instance, a screw-in ground anchor might suffice if you’re working on a small-scale project with average soil conditions in your backyard. However, rock bolts or grouted ground anchors might be more suitable for more extensive projects in challenging environments, such as stabilizing slopes with a high risk of landslides.

When selecting an anchor, it’s also essential to consider factors like the anchor’s load-bearing ability, installation requirements, and durability. If you’re unsure, consulting a professional or a reputable ground anchor supplier can provide you with valuable guidance. Whether you’re anchoring a tent in your backyard or stabilizing a massive construction project, choosing the right ground anchor can make all the difference in your venture’s safety, stability, and success.

Maintaining Your Ground Anchors

Maintaining your ground anchors is vital to ensure their functionality and effectiveness. It’s essential to perform periodic inspections, such as assessing the condition of the anchor and checking for signs of corrosion, wear, or loosening. If the environment is highly corrosive, applying an anti-corrosion coating or treatment before installing the anchor can ensure its lifespan doesn’t wane.

For screw-in ground anchors, check whether they stay securely screwed into the ground and whether the anchor’s surface shows any signs of rust or wear. For deadman anchors, inspect the cables for any signs of fraying or damage.

In the case of rock bolt ground anchors, regularly checking the bolt’s tension is necessary to ensure it’s still securely anchored. Examining the grout and steel tendon for any signs of cracking or loosening is essential with grouted ground anchors.

Should any concern be detected during these checks, you must react promptly to rectify the issue. Potential solutions could involve tightening or repositioning the anchor, applying anti-corrosion treatments, or replacing the anchor if necessary. By incorporating these maintenance practices into your project, you can help enhance your anchoring system’s safety, stability, and longevity.

Jeffrey Machine: Your Trusted Partner in Ground Anchoring Solutions

Choosing the right tool for your ground anchor installation is crucial for successful drilling projects. At Jeffrey Machine, we understand that these projects aren’t just jobs; they are significant endeavors that impact the safety and well-being of your family and community. That’s why we are committed to supplying the best tooling to meet your utility needs. Our locking dog assembly, renowned for its strength and durability, is a testament to our dedication to quality. We invite you to explore our range of utility tools and experience the difference that a family-owned business committed to excellence can make. Begin your journey to safer, more secure drilling when you work with Jeffrey Machine.