All About the Benefits of Custom Drilling Tools

Custom drilling tools offer tailored solutions that improve performance in various industries. These tools provide greater efficiency, precision, and adaptability compared to standard options by addressing specific project requirements.

Industries relying on drilling operations benefit from tools designed to meet their unique challenges, creating a competitive edge. Professionals seeking optimal results often turn to custom solutions and recognize their potential to streamline operations and boost productivity.

Improved Efficiency in Drilling Operations

Tailored drilling tools significantly enhance operational efficiency. Custom designs minimize downtime by addressing common issues such as wear and tear or compatibility mismatches. The benefits of custom drilling tools include improved performance and reduced operational costs, helping businesses achieve smoother workflows.

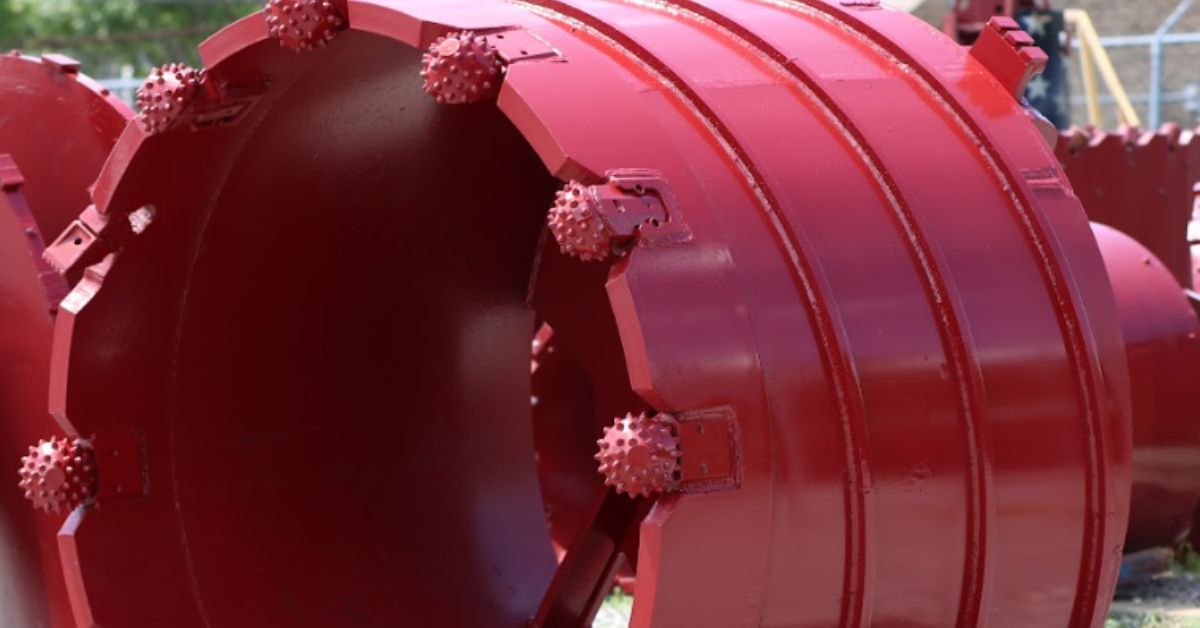

Each tool's specifications match the intended task, which leads to smoother operations and fewer interruptions. Jeffrey Machine offers auger parts and professional industrial drilling tools that align with the needs of diverse projects.

We understand that efficient tools reduce delays and operational costs, allowing businesses to maintain momentum on critical tasks. Using high-quality materials and designing innovative custom tools delivers reliability, even in demanding environments.

Customized tools optimize workflows, enabling faster project completion without compromising quality. Drilling teams save time by using tools designed to handle specific materials or conditions. Operators can rely on consistent performance with custom tools, boosting productivity across all stages of a project.

Reduced Downtime and Maintenance Needs

Frequent tool failures disrupt operations and increase expenses. Custom tools, built with durability in mind, eliminate many common causes of downtime. Features tailored to the project reduce the strain on equipment by extending their lifespan.

Maintenance teams spend less time on repairs, freeing up resources for other critical tasks. High-performance tools reduce the frequency of breakdowns, help companies experience fewer delays, and improve overall project timelines.

Faster Project Completion

Projects involving standard tools often encounter delays due to inefficiencies. Custom tools address those inefficiencies by delivering optimal performance in specific applications. Faster drilling speeds and reliable operation help teams meet tight deadlines.

Custom designs also reduce the risk of rework. Precise performance allows operators to complete tasks accurately on the first attempt. Teams achieve project milestones more quickly, benefiting both clients and contractors.

Enhanced Precision and Accuracy

Precision is key in drilling operations, where small errors can lead to costly setbacks. Custom tools provide the level of accuracy required to execute tasks with minimal deviation. Aligning tool capabilities with project demands helps operators achieve better results in less time.

Accurate drilling enhances safety and reduces material waste. Operators using tools tailored to their applications avoid unnecessary adjustments, maintaining focus on the task. Precision improves efficiency and typically results in a higher standard of work.

Tailored Designs for Unique Requirements

Every project presents unique challenges, from varying materials to different environmental conditions. Custom tools address these challenges by incorporating features that match the specific requirements of each task. Operators gain confidence knowing their tools are designed for the job at hand.

Materials, dimensions, and features are chosen based on the intended application. Drilling teams avoid the limitations of generic tools by accessing or customizing equipment that handles unique challenges effectively. This targeted approach enhances performance across a range of industries.

Advanced Technology for Precision

Modern manufacturing techniques enable the creation of highly specialized tools. Advances in technology allow for precise adjustments that maximize the effectiveness of custom designs. Operators benefit from tools that perform consistently, even under challenging conditions.

Innovative engineering contributes to reliable results. Features like optimized cutting edges or specialized coatings improve performance while reducing wear. By leveraging cutting-edge technology, custom tools meet the demands of today’s complex projects.

Versatility Across Industries

Custom drilling tools serve a wide range of industries by adapting to different operational needs. Construction, mining, and energy sectors rely on custom tools to handle their unique challenges. The adaptability of custom tools makes them an asset for professionals seeking high-performance solutions.

Tailored designs cater to various applications, from foundation drilling to material extraction. Operators use custom tools to overcome obstacles that standard options cannot address. Versatility allows for consistent results across diverse projects.

Supporting Complex Projects

Industries that undertake complex projects require tools capable of handling intricate tasks. Custom tools meet these demands by providing features that address specific challenges. Professionals rely on tailored designs to maintain accuracy and efficiency throughout their operations.

Drilling teams tackle difficult conditions, such as hard rock or unstable soil, with tools designed to perform reliably. Custom solutions reduce the risk of failure, allowing projects to progress smoothly. Customization provides the adaptability needed for even the most demanding tasks.

Reliable Solutions for Diverse Environments

Environmental conditions often dictate the success of a drilling operation. Custom tools accommodate different climates, terrains, and materials, ensuring consistent performance. Operators avoid setbacks caused by tools that cannot withstand specific conditions.

Jeffrey Machine takes pride in creating durable, high-performing tools. Our expertise helps clients navigate challenging environments with confidence. Reliable tools improve productivity and allow teams to focus on achieving their goals.

Long-Term Cost Savings

Lower operational costs translate to better returns on investment. Custom tools offer significant financial benefits by reducing expenses over time. Businesses save money on replacements and repairs by investing in high-quality equipment designed for specific tasks.

Operators who rely on custom tools experience fewer disruptions. Each tool’s extended lifespan reduces the need for frequent purchases, helping companies allocate resources more effectively. Customization provides long-term value that outweighs the initial investment.

Durability and Longevity

Custom tools endure the demands of regular use in specific applications. High-quality materials and precise engineering result in equipment that lasts longer than standard alternatives. Businesses benefit from tools that maintain performance over extended periods.

Durability reduces the frequency of repairs, saving time and money. Tools designed for specific applications experience less stress, preventing premature wear. Teams can focus on their work without worrying about equipment failures.

Optimized Performance for Maximum ROI

Investing in custom tools enhances overall project outcomes. Tools designed to meet exact requirements deliver consistent results, improving efficiency and quality. Clients and contractors alike benefit from the reliable performance of tailored equipment.

The benefits of custom drilling tools are multifaceted and go beyond just lowering operating costs. Custom drilling tools provide a higher return on investment than generic options.

Businesses that prioritize customization achieve better results in their operations. Work with Jeffrey Machine today to get the auger and drilling tools you need to make every project a success, while maximizing your ROI.