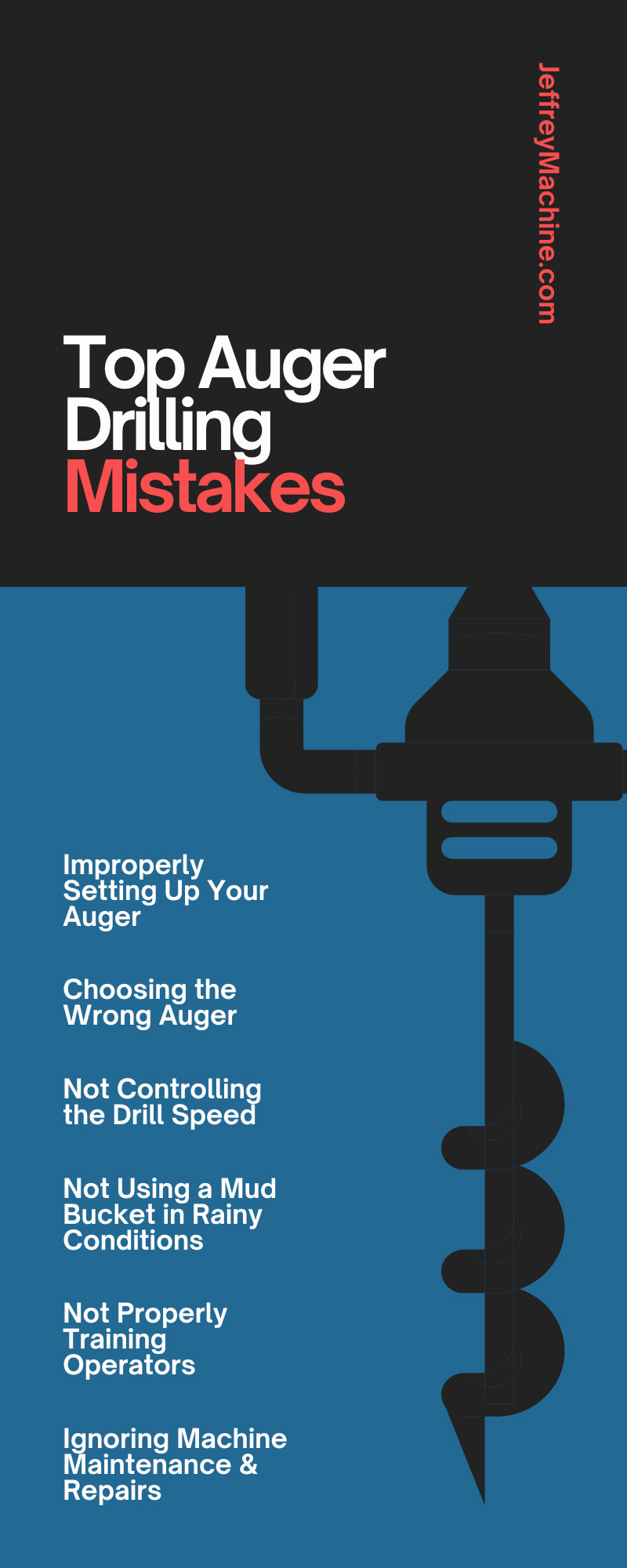

Are You Making These Top Auger Drilling Mistakes?

When someone on a jobsite makes mistakes, whether that be with improper equipment use or failure to follow instructions, it generally leads to downtime, which costs everyone involved in the project time and money. To understand the safest and most efficient ways to prevent mistakes, familiarize yourself with some of the top auger drilling mistakes that people and companies make. By avoiding these mistakes, you can complete projects promptly and fewer accidents and mishaps will take place at your work site.

Improperly Setting Up Your Auger

Your auger should operate with a stabilizer and a stabilizer pad on the ground to distribute the weight of the drill machine. These components can prevent your equipment from sinking into softer soils. You must also ensure that all the appropriate components are attached and in place before starting the engine to prevent mistakes once you begin the drilling process.

Choosing the Wrong Auger

Not every job will require the same tools and equipment. Therefore, you must be mindful of what equipment you’re using and what’s appropriate for your application. Whether the ground is frozen, wet, or rocky will determine which auger is best for your job. For example, using a pilot bit with limestone or sandstone could damage the bit beyond repair. If you were to use the wrong auger bit, you could damage your equipment, costing your business time and money to fix.

Not Controlling the Drill Speed

The speed at which your drilling auger rotates is essential for boring a hole that’s consistent in size. To better control your auger speed, you must also learn how to control torque, pressure, and rotation.

You can control torque by engaging the spring-loaded handle located on top of the hydraulic motor and through Kelly bar adapters, which transfer torque and crowd force from the rotary tool to the drilling tool. You can control rotation and pressure with the type of motor or engine you use to power the auger—you must ensure you have enough power to avoid bogging down the drill bit as it rotates into the ground.

Not Using a Mud Bucket in Rainy Conditions

When conditions on the work site are rainy or muddy, drilling can be messy—removing mud or water from a hole is difficult. A mud bucket, however, can help you remove mud and dirt from a bore, making your job much easier. Displacing the wet soil is necessary for drilling clean holes free of excess materials.

Not Properly Training Operators

After many years in the industry, operators develop a natural feel for their craft, but they still need the proper training to operate drilling equipment. Regardless of the their background and education, when you hire an employee, you must provide them with adequate training so that they can perform their job duties efficiently and safely.

Ignoring Machine Maintenance & Repairs

One drilling mistake you could be making is not inspecting, maintaining, or repairing your equipment. Your machine cannot perform to the best of its ability if you do not properly maintain and repair it. You must inspect the equipment before each working day to determine if anything on the auger needs maintenance. Follow the manufacturer’s instructions for fixing the equipment, and ensure all components are attached securely before using the auger on the work site.

Ignoring Common Hazards

Ignoring common safety hazards on the work site is never in your best interest. Lack of safety precautions can severely or fatally injure yourself or other employees. Working with the drilling equipment can be cumbersome, so operators and ground workers must collaborate to form clear communication and safety measures.

Some common hazards workers encounter include the auger coming in contact with underground or overhead powerlines; obstacles; modified equipment; and disabled safety controls. To prevent catastrophe, follow the operator’s manual instructions for operating the drilling auger. Use the equipment as intended without modifications, and direct people away from the auger when it’s in use.

Not Checking Site Conditions

Failure to double-check your work site conditions could lead to slips, trips, and falls. When the site's conditions threatens your equipment's integrity, you should take extra precautions to ensure you do not make mistakes.

The condition of the soil plays a major role in whether your equipment will be sufficient for the job. For example, wet soil or frozen ground will require different tactics for drilling efficiency. Assess the condition of the work site before starting your operations—this is the best way to prevent soil condition mistakes.

Not Covering a Hole or Posting Signs

After you finish boring a hole into the earth, you leave behind a safety hazard that workers can fall into if you do not cover or mark the location. These holes can be dangerous without the proper safety measures in place. When you finish an application and move on to the next, mark the hole to warn employees that they’re in an area where they could fall.

Ignoring Previous Mistakes

Incidents within the piling and drilling industries happen very rarely. But when they do, businesses must learn from them so that they can avoid making the same mistakes later on their work sites. For example, operating equipment on a too-steep slope can cause a rig to collapse or place employees in hazardous situations. Remain up to date on industry and safety standards to prevent accidents like this from happening on your work sites.

Leaving the Auger Rotating Between Holes

Once you complete the digging of one hole, turn off the piece of machinery with the auger attachment before moving to another location on the jobsite. Leaving the tool rotating could cause injuries to unsuspecting workers in the vicinity. The best practice is to make sure the auger blade is not rotating after you’re done using it before digging at the next site.

Your auger tool must be in a suitable condition to perform its job duties. Never make the mistakes above; take the time to understand the attachment before using it to avoid damaging or ruining it. If you have questions regarding your auger tools, contact Jeffrey Machine to speak with one of our professionals and work through any concerns you might have about your product or what product is appropriate for your application.