The Complete Guide to Different Types of Augers

In this complete guide to different types of augers, you will learn what tooling is best for certain ground conditions. Contractors will come together to determine which auger is appropriate for the needs of the work site and the best way to bore holes through a material, such as dirt or rock. One attachment might perform better in some situations than another.

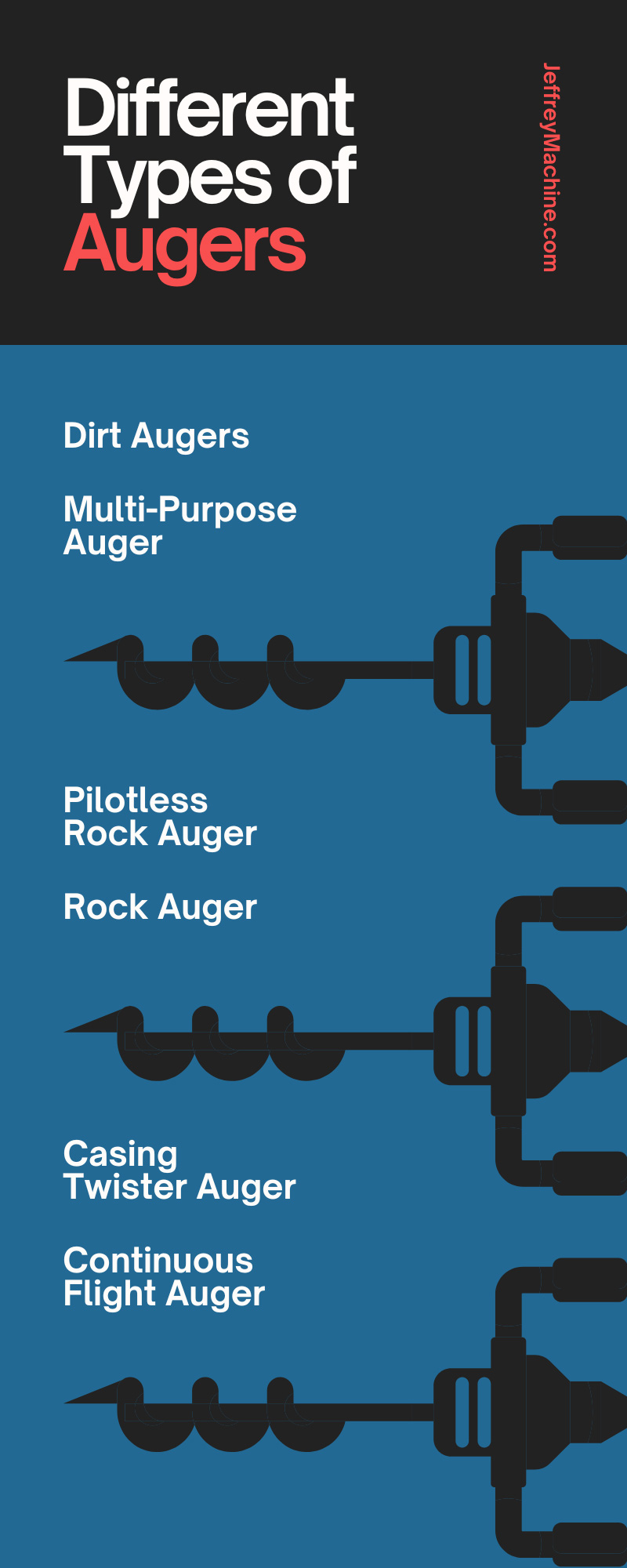

At Jeffrey Machine, we have six different auger tools available for purchase on our website. Each one is unique in strength and durability and suitable for various materials. In this article, we list them in order from least to most aggressive. Review our list to find the most appropriate tool for your project.

What Do the Types Mean?

Categorize our auger tools into six types based on what our customers typically call for—one through six. Type one is considered the most aggressive and abrasive tool to use when boring holes, and six is the least aggressive with a flatter bottom. In general, a sharper spiral pattern at the bottom of the auger makes it more aggressive at displacing and drilling through various materials.

About Jeffrey Machine’s Augers

Jeffrey Machine prides itself on expertly engineered augers to give our customers the best possible products. Our foundation augers come with a fabricated steel box in all sizes, beveled flighting on all augers, and a high-quality standard. All 30-inch and larger heavy-rock augers come with laminate to increase the strength of the flighting. The laminate is available for dirt augers upon request. Below, we’ll go through the most important products on our website—learn more about them before choosing one for your construction application.

Dirt Augers

Dirt augers are used on work sites to drill holes through the Earth’s surface when only soil is beneath. The bottom of this tool is flat, with the flighting wrapping around the hub. This tool is particularly great at making holes for concrete footing installation.

The dirt auger on our website is considered a type six and the least aggressive of our bunch. While a rock auger can drill through the soil, a dirt auger cannot drill through rock. If more rigid materials exist in the ground, you will need to choose a different tool.

Multi-Purpose Auger

The multi-purpose auger can perform jobs through soil and rocky terrain. When the work site has sporadic rocky material throughout, this tool makes it easy to switch between dirt and rock teeth attachments to get the job done efficiently. Simply exchange the teeth mounted at the bottom of the tool to tackle different levels of soil.

This auger tool may be multi-purpose, but it’s still considered a type six and the least aggressive. However, this tool has a special component: It can make the diameter of your hole larger by switching from a gauge tooth to a BFZ shovel tooth. A multi-purpose auger can add three inches to your hole’s diameter!

Pilotless Rock Auger

Another auger you can choose from on our website is the pilotless rock auger. This attachment will perform best when you need to drill through malleable rock. With this tool, you can use .990 or 38mm rock series wear parts. Conical teeth are available upon request.

This type-six auger utilizes wear pads to increase the lifespan of your tool. Once these pads wear down, you can easily weld a new one to prevent further damage to the attachment.

Rock Auger

When many rocks are present below the Earth’s surface, your construction crew will need a rock auger to tackle the job of drilling holes appropriately. Rock augers are suitable tools when the ground is frozen or there is a layer of permafrost.

The best thing about Jeffrey Machine’s rock auger is that you can change the teeth configurations and the teeth you use to make this tool type one through six. This also means you can curate it as aggressively as you need it to be. Augers made with carbide teeth provide more downforce power to drill through hard, cumbersome materials.

Casing Twister Auger

Another attachment that is exchangeable with all types is the casing twister auger. This tool is unique because it’s helpful in many applications, including wet soil mixing, ground release drilling, rock drilling, or casing while drilling (CwD).

Just like the rock auger, you can alter this tool from less to more aggressive depending on what you need from the equipment. You can use any tooth configuration with this auger to adjust its aggressiveness.

Continuous Flight Auger

Continuous flight augers are great for creating deep concrete foundations. This tool is unique because—as a borehole is drilled and the material is displaced by the continuous flighting—the hole is injected with concrete from the tool as you extract from it. This helps to create a pile without exposing the hole.

The aggressiveness of these augers range between types three, four, five, and six. Use the concrete poured from this tool to make retaining walls or reinforcements to protect workers as they excavate the work site.

Bonus: Core Barrel

Now that you have the complete guide to our different types of augers, we’ve included a bonus component—a core barrel. It may be used in conjunction with a rock auger when other conventional auger tools are not working efficiently to break up hard rock. The layout of the teeth on this barrel comes in three, five, or seven rows. Consider adding the core barrel to your collection for extra force when one or more of your tools are not working effectively for a construction job.

Choosing the appropriate auger for your application is essential. Otherwise, you could damage or break one of your tools. Keep in mind that the different types, one through six, are on our website. We can help you decide which tool will be the most aggressive for your application. Consider the conditions on the work site before drilling any holes through the Earth. If you have any questions, contact our team—we’d be happy to help!